Canned motor pumps of CH series

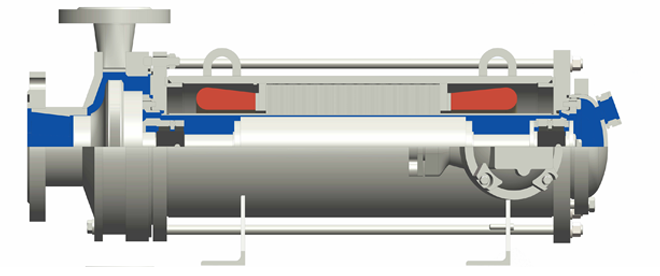

CANNED MOTOR PUMPS OF CH SERIES, TYPES 1,4

| Productive capacity: | 3,2 - 100 m3/h |

| Pumping head: | 12,5 - 125 m; |

| Rotary speed: | 1500 - 3000 min-1; |

| Working temperature: | max. +50 °C |

| Viscosity | up to 50 mm2/s; |

| Pressure in the circuit: | up to 50 bar; |

| Engine power: | 1,1 - 37 kWt. |

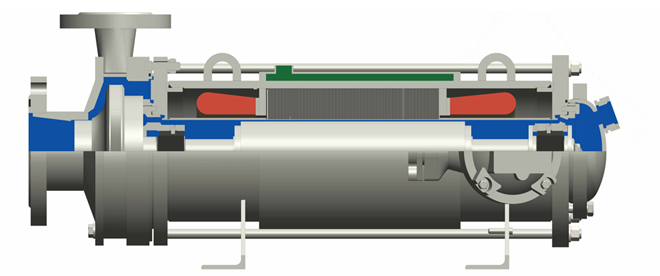

Canned motor pumps of CH series, types 2, 5

| Productive capacity: | 3,2 - 200 m3/h |

| Pumping head: | 12,5 - 200 m; |

| Rotary speed: | 1500 - 3000 min-1; |

| Working temperature: | max. +100 °C |

| Viscosity | up to 50 mm2/s; |

| Pressure in the circuit: | up to 50 bar; |

| Engine power: | 1,1 - 132 kWt. |

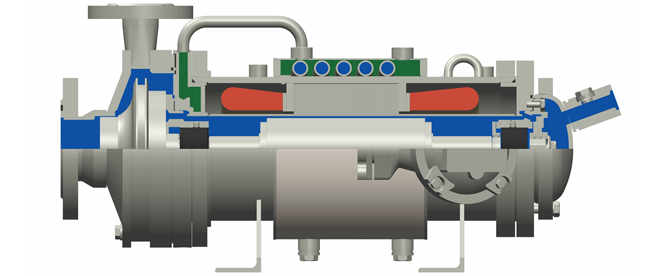

Canned motor pumps of CH series, types 3, 6

| Productive capacity: | 3,2 - 200 m3/h |

| Pumping head: | 12,5 - 125 m; |

| Rotary speed: | 1500 - 3000 min-1; |

| Working temperature: | max +360 °C |

| Viscosity | up to 50 mm2/s; |

| Pressure in the circuit: | up to 50 bar; |

| Engine power: | 1,1 - 75 kWt. |

Example of a conventional designation of the CH type canned motor pump pumping liquids with a density of up to 1000 kg/m3, a viscosity of up 1 cSt, with protection against explosion 1ExdsIIBT4 X:

Notes

- viscosity of up to 40 cSt;

- temperature (see table).

- availability of solid nonabrasive impurities – a size of up to 0,2 mm and up to 0.2% in terms of weight is admitted.

2. The parameters in the Table are given for operating fluid of a density of 1000 kg/m3 and a viscosity of 1 cSt.

3. When pumping liquids with a density of over 1000 kg/m3 and (or) taking into account viscosity, electric pumps are supplied with reduced pressure due to impeller turning on the outside diameter in order to avoid overloading of the motor.

4. Electric pumps of the less rated power of the same standard size, for example, 1CH 25/50-5,5-1 (2,3,4,5,6), are intended for pumping liquid of a density of up to 850 kg/m3.

5. Electric pumps are made at 380, 500, 660 V (specified when ordering), a current frequency of 50 Hz.

6. Mark of explosion protection:

- for electric pumps versions 1, 2, 4, 5 - 1ExdsIIBT4 X;

- for electric pumps versions 1C, 2C, 5C - 1ExdsIICT4 X;

- for electric pumps versions 3, 6 - 1ExdsIIBT1 - T4 X;

- for electric pumps versions 6 C - 1ExdsIICT1 - T4 X.

7. Electric pumps are available in the following versions depending on the material:

- A - carbon steel;

- E - stainless steel 1.4571, 12Х18H12M3TЛ;

- K - stainless steel 1.4878, GX10CrNi18-8;

- K1 - economically alloyed steel 12X21H5T, 10X21H5TЛ.

More detailed information, including graphic specifications, schemes of binding and control, description of the structure, installation and operation rules, are specified in the operational documentation of the electric pump.

Basic Parameters of Electric Pumps

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

|

CH 6,3/20-1,1-2 (5)

|

6,3

|

20

|

2,5-9,5

|

0,9

|

1,1

|

-40...+100

|

W/L

|

|

CH 6,3/20-1,1-3

|

6,3

|

20

|

2,5-9,5

|

1,2

|

1,1

|

+100...+360

|

L

|

|

CH 6,3/32-2,2-2 (5)

|

6,3

|

32

|

2,0-9,5

|

0,9

|

2,2

|

-40...+100

|

W/L

|

|

CH 6,3/32-2,2-3

|

6,3

|

32

|

2,0-9,5

|

1,2

|

2,2

|

+100...+360

|

L

|

|

CH 12,5/50-4-2 (5)

|

12,5

|

50

|

3,5-18

|

1,0

|

4,0

|

-40...+100

|

W/L

|

|

CH 12,5/50-4-2С

|

12,5

|

50

|

3,5-18

|

1,0

|

4,0

|

-40...+100

|

W/L

|

|

CH 12,5/50-4-3 (6)

|

12,5

|

50

|

3,5-18

|

1,0

|

4,0

|

+100...+360

|

L

|

|

CH 25/12,5-3Б-1

|

25

|

12,5

|

17,5-37,5

|

0,8

|

3,0

|

-40...+40

|

W/L

|

|

CH 25/20-3-2 (5)

|

25

|

20

|

18-36

|

2,6

|

3,0

|

-40...+100

|

W/L

|

|

CH 25/20-3-3 (6)

|

25

|

20

|

18-36

|

1,9

|

3,0

|

+100...+360

|

L

|

|

CH25/50-7,5-1 (4)

|

25

|

50

|

15-37,5

|

1,5

|

7,5

|

-40...+40

|

W/L

|

|

CH 25/50-7,5-1С

|

25

|

50

|

15-37,5

|

1,5

|

7,5

|

-40...+40

|

W/L

|

|

CH 25/50-7,5-2 (5)

|

25

|

50

|

15-37,5

|

1,5

|

7,5

|

+40...+100

|

L

|

|

CH 25/50-7,5-3 (6)

|

25

|

50

|

15-37,5

|

1,8

|

7,5

|

+100...+360

|

L

|

|

CH 25/50-7,5-5С

|

25

|

50

|

15-37,5

|

1,5

|

7,5

|

+40...+100

|

L

|

|

CH 25/50-5,5-1 (4)

|

25

|

50

|

15-37,5

|

1,5

|

5,5

|

-40...+40

|

W/L

|

|

CH 25/50-5,5-2 (5)

|

25

|

50

|

15-37,5

|

1,5

|

5,5

|

+40...+100

|

W/L

|

|

CH 25/50-5,5-3 (6)

|

25

|

50

|

15-37,5

|

1,8

|

5,5

|

+100...+360

|

L

|

|

CH 25/80-15-4

|

25

|

80

|

10-40

|

1,8

|

15,0

|

-40...+40

|

W/L

|

|

CH 25/80-15-5

|

25

|

80

|

10-40

|

1,8

|

15,0

|

+40...+100

|

L

|

|

CH 25/80-15-5С

|

25

|

80

|

10-40

|

1,8

|

15,0

|

+40...+100

|

L

|

|

CH 25/80-11-4

|

25

|

80

|

10-40

|

1,5

|

11,0

|

-40...+40

|

W/L

|

|

CH 25/80-11-5

|

25

|

80

|

10-40

|

1,5

|

11,0

|

+40...+100

|

L

|

|

CH 25/80-11-5С

|

25

|

80

|

10-40

|

1,5

|

11,0

|

+40...+100

|

L

|

|

CH 25/80-11-6

|

25

|

80

|

10-40

|

1,5

|

11,0

|

+100...+360

|

L

|

|

CH 50/12,5-5,5B-1

|

50

|

12,5

|

35-65

|

1,0

|

5,5

|

-40...+40

|

W/L

|

|

CH 50/50-15- 1 (4)

|

50

|

50

|

25-75

|

2,3

|

15,0

|

-40...+40

|

W/L

|

|

CH 50/50-15-2 (5)

|

50

|

50

|

25-75

|

2,3

|

15,0

|

+40...+100

|

L

|

|

CH 50/50-15-3

|

50

|

50

|

25-75

|

2,3

|

15,0

|

+100...+360

|

L

|

|

CH 50/50-15-5С

|

50

|

50

|

25-75

|

2,3

|

15,0

|

+40...+100

|

L

|

|

CH 50/50-5-6С

|

50

|

50

|

25-75

|

2,3

|

15,0

|

+100...+360

|

L

|

|

CH 50/50-11-1 (4)

|

50

|

50

|

25-75

|

2,3

|

11,0

|

-40...+40

|

W/L

|

|

CH 50/50-11-2 (5)

|

50

|

50

|

25-75

|

2,3

|

11,0

|

+40...+100

|

L

|

|

CH 50/50-11- 3 (6)

|

50

|

50

|

25-75

|

2,5

|

11,0

|

+100...+360

|

L

|

|

CH 50/50-11-5С

|

50

|

50

|

25-75

|

2,3

|

11,0

|

+40...+100

|

L

|

|

CH 50/50-11-6С

|

50

|

50

|

25-75

|

2,5

|

11,0

|

+100...+360

|

L

|

|

CH 50/80-К-18,5М-4L

|

50

|

80

|

25-75

|

2,2

|

18,5

|

-100...-40

|

W/L

|

|

CH 50/80-22-4

|

50

|

80

|

25-75

|

2,2

|

22

|

-40...+40

|

W/L

|

|

CH 50/80-22-5

|

50

|

80

|

25-75

|

2,2

|

22

|

+40...+100

|

L

|

|

CH 50/80-22-6

|

50

|

80

|

25-75

|

2,2

|

22

|

+100...+360

|

L

|

|

CH 50/125-37-5

|

50

|

125

|

25-75

|

2,2

|

37

|

-40...+100

|

L

|

|

CH 100/32-15-1 (4)

|

100

|

32

|

65-140

|

3,5

|

15,0

|

-40...+40

|

W/L

|

|

CH 100/32-15-2 (5)

|

100

|

32

|

65-140

|

3,5

|

15,0

|

+40...+100

|

L

|

|

CH 100/32-15-3 (6)

|

100

|

32

|

65-140

|

3,5

|

15,0

|

+100...+360

|

L

|

|

CH 100/32-11-1 (4)

|

100

|

32

|

65-140

|

3,5

|

11,0

|

-40...+40

|

W/L

|

|

CH 100/32-11-2 (5)

|

100

|

32

|

65-140

|

3,5

|

11,0

|

+40...+100

|

L

|

|

CH 100/32-11-3 (6)

|

100

|

32

|

65-140

|

3,5

|

11,0

|

+100...+360

|

W/L

|

|

CH 100/32-11-6С

|

100

|

32

|

65-140

|

3,5

|

11,0

|

+100...+360

|

L

|

|

CH 100/50-30-4

|

100

|

50

|

70-140

|

3,8

|

25,0

|

-40...+40

|

W/L

|

|

CH 100/50-30-5

|

100

|

50

|

70-140

|

3,8

|

25,0

|

+40...+100

|

L |

|

CH 100/50-30-5С

|

100

|

50

|

70-140

|

3,8

|

25,0

|

+40...+100

|

L

|

|

CH 100/80-37-5

|

100

|

80

|

65-140

|

3,0

|

37

|

-40...+100

|

L

|

|

CH 100/80-37-6

|

100

|

80

|

65-140

|

3,3

|

37

|

+100...+360

|

L

|

|

CH 100/125Н-К-55М-4L

|

100

|

125

|

65-140

|

2,0

|

55,0

|

-70...+30

|

L

|

|

CH 100/125-75-5

|

100

|

125

|

65-140

|

3,0

|

75

|

-40...+100

|

L

|

|

CH 100/125-75-6

|

100

|

125

|

65-140

|

3,0

|

75

|

+100...+360

|

L

|

|

CH 100/200-132-5

|

100

|

200

|

30-150

|

3,0

|

132,0

|

-40...+100

|

L

|

|

CH 200/50-37-5

|

200

|

50

|

100-300

|

4,8

|

37,0

|

-40...+100

|

L

|

|

CH 200/50-45-5

|

200

|

50

|

100-300

|

4,8

|

45,0

|

-40...+100

|

L |

|

CH 200/80-75-6

|

200

|

80

|

150-250

|

4,5

|

75,0

|

+100...+360

|

L

|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |